Features

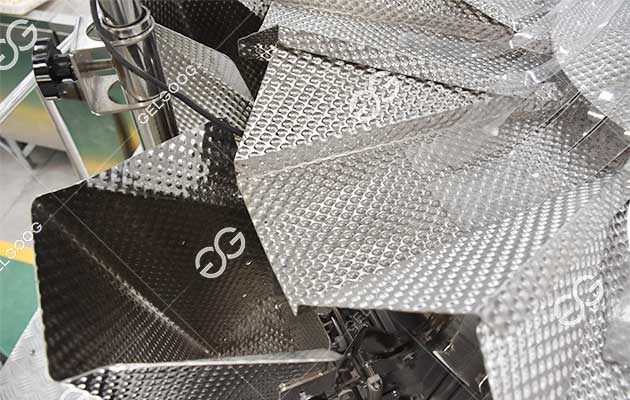

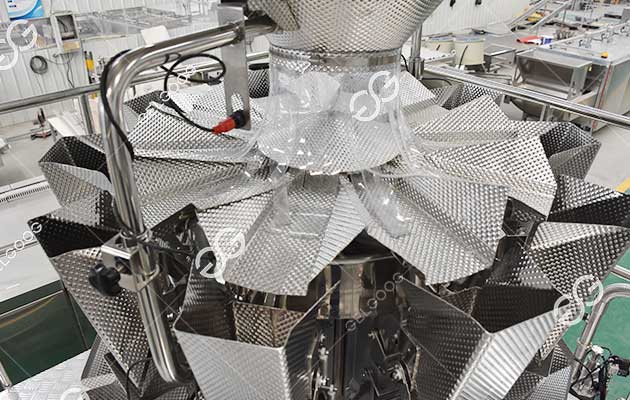

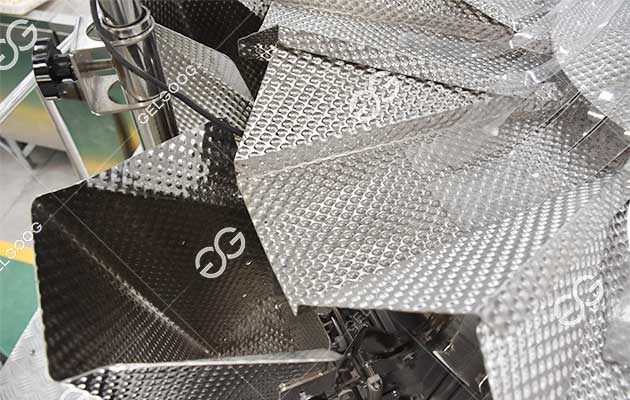

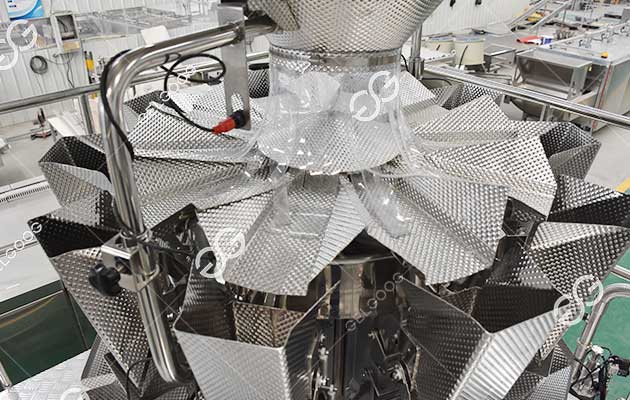

Multi Head Weighing Packaging Machine is an efficient and accurate automated equipment, widely used in quantitative weighing and packaging of food.

Working Principle

- Multi Head Weighing Packaging Machine weighs materials through multiple weighing heads at the same time. Each weighing head works independently and can measure the weight of the material quickly and accurately.

- According to the preset weight value, the machine will automatically select a combination of multiple weighing heads to make the total weight closest to the target value, thereby achieving high-precision weighing.

Main Features of Multi Head Weighing Packaging Machine

- High-precision weighing: The use of high-precision special sensors can ensure the accuracy of weighing.

- High-speed packaging: Multiple weighing heads work at the same time, greatly improving the packaging speed.

- High flexibility: The number and combination of weighing heads can be adjusted according to different packaging requirements.

- Strong adaptability: Suitable for packaging of various granular, powdery, blocky and other materials.

- High degree of automation: Combines automatic weighing and packaging functions to reduce manual intervention.

Application areas

- Multi-head weighing and packaging machines are widely used in the food industry, including but not limited to the following foods:

- Puffed foods: such as potato chips, shrimp strips, onion rings, etc.

- Nuts and fried foods: such as peanuts, melon seeds, pistachios, etc.

- Grains: such as rice, corn, oatmeal, etc.

- Snacks: such as candy, biscuits, popcorn, etc.

- Frozen foods: such as frozen vegetables, frozen meat, etc.

- Pet food: such as pet snacks, pet dry food, etc.

Advantages of multi-head weighing and packaging machines

- Improve production efficiency: Able to complete the weighing and packaging of a large number of materials in a short time.

- Reducing labor costs: High degree of automation reduces manual intervention.

- Improve product quality: High-precision weighing can ensure that the weight of the material in the package meets the standard.

- Reducing waste: Reduce material waste through accurate weighing.

- Meeting hygiene standards: The equipment is easy to clean and meets the hygiene requirements of the food industry.

Factors to consider when choosing a multi-head weighing and packaging machine

- Product type: Different foods have different requirements for weighing accuracy and packaging form.

- Weighing speed and accuracy: Choose the appropriate weighing speed and accuracy according to production needs.

- Equipment cleaning and maintenance: The food industry has high requirements for equipment cleaning and maintenance, and it is necessary to choose equipment that is easy to clean and maintain.

- Price and cost-effectiveness: Choose cost-effective equipment according to your budget.

Technical Data

FAQ

Message

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.